- Home

-

Products

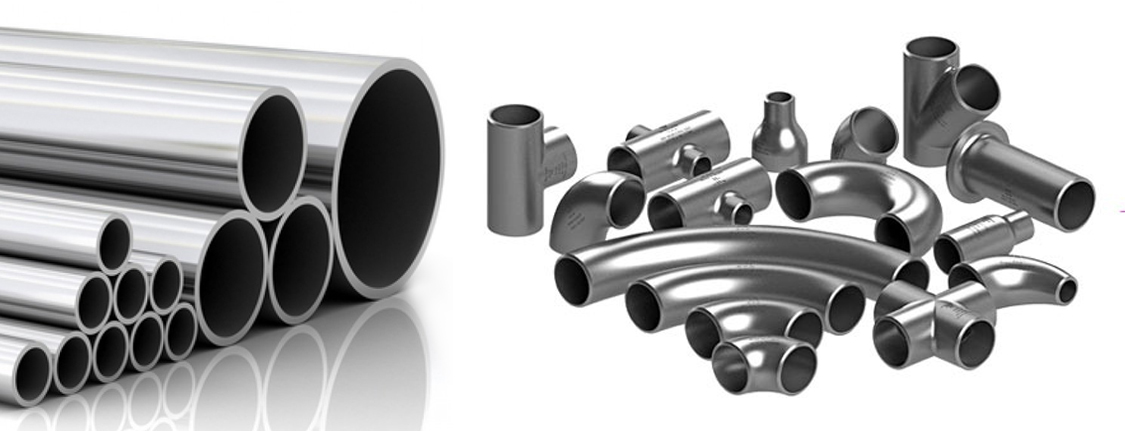

- STAINLESS STEEL PIPE FITTINGS

- STAINLESS STEEL BOILER, SMLS TUBES AND PIPES

- STAINLESS STEEL Dairy PIPES AND Dairy Fittings

- FERRULE FITTINGSICOMPRESSION FITTINGS

- Stainless Steel Plates, Sheet Coil , Chequered Plates

- Stainless Steel Angles, and Channels

- Stainless Steel Flats, Bars,-Hex–Square Bars

- FABRICATED/FLANGED PIPES, FITTINGS

- SS FLEXIBLE HOSE PIPES

- Stainless STEEL FASTENERS

- INVESTMENT CASTING-IC FITTINGS

- PLATE CIRCLES, RINGS, FORGINGS

- STAINLESS STEEL & BRASS VALVES

- COPPER TUBES PIPES, BRASS VALVES & FITTINGS

- HIGH PRESSURE VALVES & FITTINGS

- STAINLESS STEEL Hand Railing Pipe Fittings

- STAINLESS STEEL Hand Railing Pillar, Designs

- CARBON STEEL PIPE FITTINGS

- ALLOY STEEL PIPE FITTINGS

- CAST IRON / STEEL VALVES GUNMETAL VALVES

-

Special Grades

- 2205 DUPLEX PIPES & FITTINGS

- COPPER NICKEL PIPE FITTINGS

- STAINLESS STEEL 904L PIPE FITTINGS

- MONEL PIPE FITTINGS | PIPES

- INCONEL PIPE FITTINGS

- ALLOY 20 FITTINGS

- STAINLESS STEEL 201/202 PIPE FITTINGS

- SS 304/304L PIPE & PIPE FITTINGS

- STAINLESS STEEL 304/304L WELDED PIPES

- SS 310S PIPE & PIPE FITTINGS

- SS 316/316L PIPE & PIPE FITTINGS

- 317L PIPE FITTINGS

- 321/321H PIPE FITTINGS

- 347/347H PIPE FITTINGS

- ButtWeld Fittings

- Forged Fittings

- Flanges

- Price List

- Clients

- Contact Us